Advanced measurement technology for the industrial needs of

Värnamo Mätcenter AB.

Accurate measurements, advanced technology and long experience since 2001.

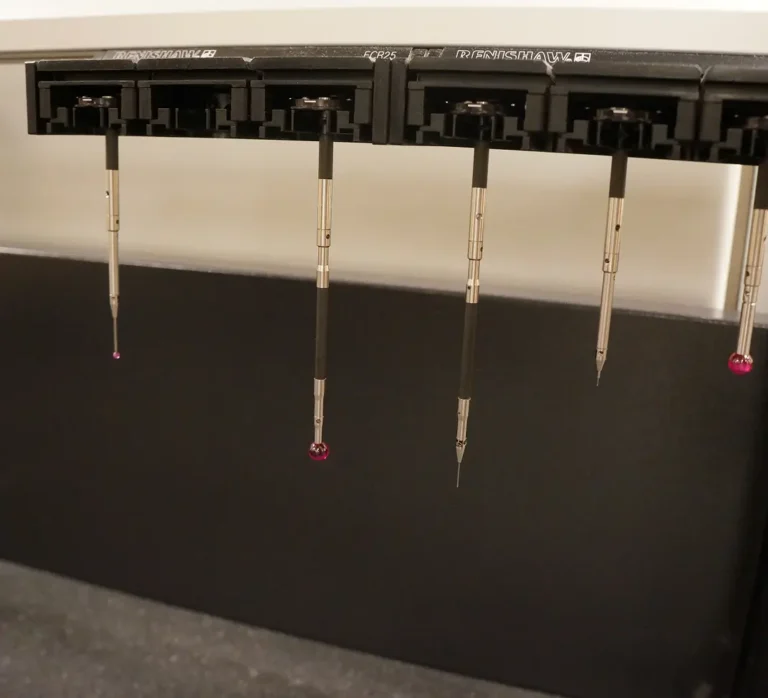

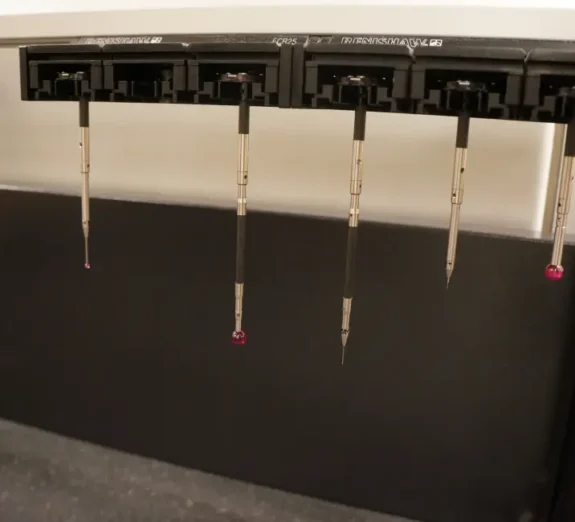

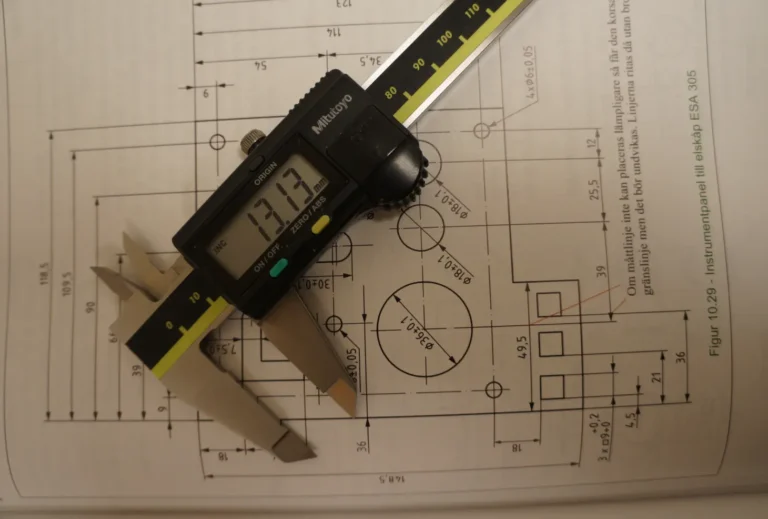

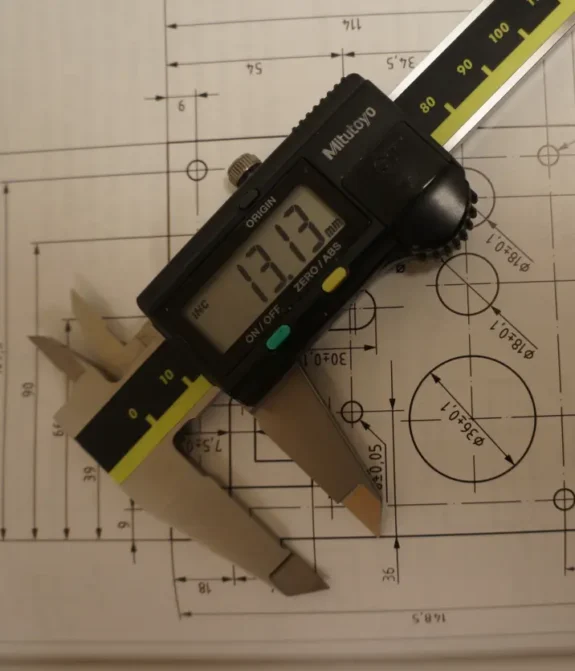

CMM measurement in 2D and 3D environment and drawing reading

We perform CMM measurement with high precision and repeatable accuracy. Our measurement technicians handle everything from single components to complete series and verification of jigs, gauges and fixtures. Capability measurements, drop-out tests and full-cycle tests are used to ensure stable production, correct tolerances and documented quality in manufacturing.

Reading drawings and analysing CAD data is a central part of our work and contributes to effective measurement strategies, reduced error margins and traceable documentation. Our measurement technology is used by industrial companies throughout the Nordic region that place high demands on reliability, repeatable precision and accurate results in every measurement.

Programming in Metrologic

We programme in Metrologic to achieve accurate and repeatable measurement results. The measurements are made against both drawings and CAD documents. The combination of 2D and 3D enables advanced analysis. The results are documented digitally and delivered in traceable formats according to customer requirements.

Our measurement technicians have extensive experience in creating efficient measurement programmes that provide reliable data regardless of product shape, material or tolerances. The modern programme environment is a central part of our quality assurance and contributes to short lead times and high precision in every assignment.

Experience, precision and modern equipment

Värnamo Mätcenter AB has been operating since 2001 and is based in Värnamo. We have around 500 customers in the Nordic region and northern Europe, mainly in the automotive and manufacturing industries. The company often works with classified products and development projects where precision and discretion are crucial.

At our premises in Hornaryd's industrial area, four measurement technicians work full-time with four CNC-controlled coordinate measuring machines. The software is continuously updated to comply with the latest standards. The combination of experience, technology and accuracy makes us a reliable partner for the measurement needs of industry.